-

-

-

ISO 9001:2015

Issuing authority : XINGYUAN

Valid period : 2021/3/15 - 2024/3/14

ISO9001 does not refer to a standard, but a class of standards collectively, is formulated by TC176 (TC176 refers to the quality management system technical committee) of all international standards, is ISO12000 standards in the most popular, the most common products.ISO9001 quality management system certification standard is many countries, especially developed countries over the years management theory and management practice development summary, it reflects a management philosophy and quality management method and model, has been used by more than 100 countries and regions in the world.ISO9001 International quality management system standard is so far the world's most mature a set of management systems and standards, is the foundation of enterprise development and growth.ISO9001 was transformed from the world's first quality management system standard BS 5750 (written by BSI). Iso 9001 is by far the world's most mature quality framework, being used by more than 750,000 organizations in 161 countries/regions. ISO 9001 not only for the quality management system, but also for the overall management system to set the standard. It helps organizations succeed through improvements in customer satisfaction, employee motivation, and continuous improvement.Entering the 21st century, the pace of information development is accelerating, many enterprises to reconstruct the information to realize the power of their core competitiveness, QIS quality management information system has been fully applied and promoted in the automobile, electronics and other industries, to support the ISO9001 quality management system to provide a platform support, And embedded standard QC seven techniques, TS five manuals, quality management model, make ISO9001 quality management system digitalization possible.ISO9001 certificationAccording to the International Organization for Standardization (ISO) in November 2007 released the latest survey results show that by the end of 2006, in 170 countries issued a total of ISO9001:2000 version of the certificate 897866, among which China issued 162259 certificates, 18% of the total issued, ranked first in the world. This shows that the 2000 version of the standard has been widely used, received the attention of many organizations, China has also become a real quality management system certification country.The characteristics ofThe independent third party quality system certification was born in the late 1970s, which evolved from the product quality certification. ISO9001 quality system certification has the following characteristics:1. The object of certification is the quality system of the supplier. The object of quality system certification is not a product or service of the enterprise, but the quality system itself. Of course, the quality system certification is bound to involve the products or services covered by the system. Some enterprises apply for the certification of the total quality system including all kinds of products or services of the enterprise, and some applications only include the quality system certification of a certain or part of the products (or services). Although involved in the scope of products are large and small, and the object of certification is the quality system of the supplier.2. Certification is based on quality assurance standards. Quality system certification, often is the supplier in order to provide external quality assurance needs, so the certification basis is the quality assurance model standard. In order to make the quality system certification and international practice to achieve mutual recognition standards, the supplier had better choose ISO9001:2015 standard.3. The certification body is a third-party quality system evaluation institution. In order to make the supplier quality system certification can have impartiality and credibility, the certification must be with the certified unit (supplier) in the economy has no interest, no administrative affiliation of the third party institutions to bear. In addition to having experienced, well-trained personnel, resources and procedures in line with the requirements, this organization must also win the support of the government and the trust of the society with its excellent certification practice, with authority and impartiality.4. The identification of certification approval is registration and issuance of certificates. According to the prescribed procedures to apply for certification of the quality system, when the assessment results are judged to be qualified, by the certification authority to the certification enterprise to give registration and issued a certificate, listed in the quality system certification enterprise directory, and publicly released. Approved certification of enterprises, can be used in promotional materials, trade fairs and other promotional activities, but the logo shall not be directly used in the product or its packaging, so as not to be confused with product certification. The registration mark shall be protected by law and shall not be used fraudulently or forged.5. Certification is the independent behavior of enterprises. Product quality certification, can be divided into two categories of safety certification and quality certification, safety certification is often a mandatory certification. Quality system certification, mainly in order to improve the quality of the enterprise reputation and expand sales, generally enterprises voluntarily, actively put forward the application, is an enterprise independent behavior. But do not apply for certification of enterprises, often by the market naturally formed pressure of distrust or trade barriers pressure, and forced enterprises have to fight for entry into the ranks of certified enterprises, but this is not the certification system or the mandatory role of government decrees.applyThe ISO 9001 quality management system is suitable for any organization that wants to improve the way it operates and manages, regardless of its size or division. However, to get the best return on investment, the company should be prepared to implement the system throughout the organization, not just within specific sites, departments or divisions.In addition, ISO 9001 is compatible with other management system standards and specifications, such as OHSAS 18001 Occupational Health and Safety Management system and ISO 14001 Environmental management system. They can be seamlessly integrated through "integration management". They share many common principles, so choosing an integrated management system can bring great economic benefits.Content of the certificateSample ISO9001 certificate in both Chinese and EnglishSample ISO9001 certificate in both Chinese and EnglishThe name of the certification body, the name of the certification application unit and the relevant standards approved by the product audit, the validity period of the certificate, the certificate number, the official seal of the certification body, the signature of the person in charge of the certification body, etc.

-

-

-

-

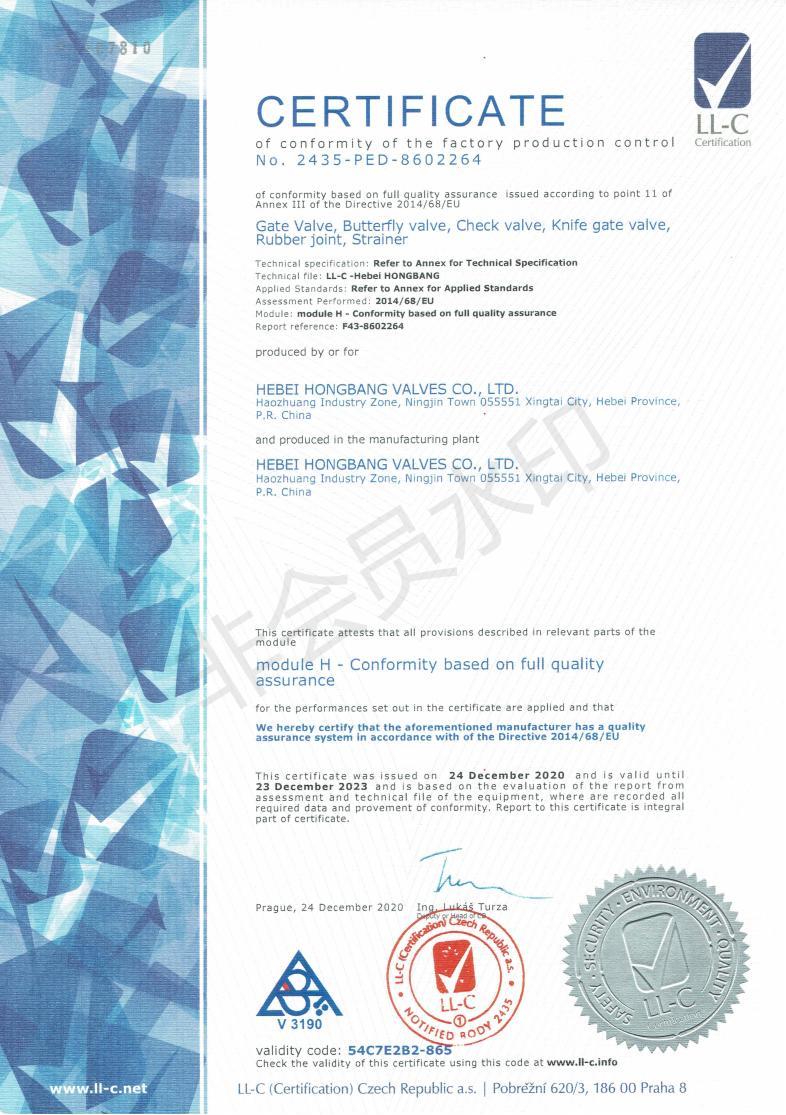

2435-PED-2021 HONGBANG_00

Issuing authority : LL-C

Valid period : 2020/12/23 - 2023/12/23

-

-

-

-

2435-PED-2021 HONGBANG_01

Issuing authority : LL-C

Valid period : 2020/12/23 - 2023/12/23

PED was adopted on May 29, 1997, and took effect on November 29, 1999. There is a 30-month grace period before May 28, 2002, that is, products can choose to apply PED or the original regulations of each country (but those applicable to the original regulations of each country can only be circulated in that country). From May 29, 2002, the original regulations of various countries will be abolished, and PED becomes the compulsory regulation of pressure equipment in Europe.PED Certification Full name: Pressure Equipment (PED) certification. PED is a compulsory regulation issued by the member states of the European Union on the safety of pressure equipment.The difference betweenIf a simple comparison is made with ASME certification, PED certification is the safety certification of specified products, while ASME certification is the factory certification of specified standards. This is the biggest difference in nature between the two. It is worth paying attention to that in PED certification, the basic safety requirements stipulated by the directive are enforced, but the technical standards of the products are not. Unless specified by the user, the manufacturer is free to choose any technical standard. This point and domestic provisions: must be mandatory implementation of national standards, ministerial standards or industry standards is also very different.PEDThe Pressure Equipment Directive PED 2014/68/EU is a directive. All equipment with design pressure over 0.5bar, regardless of its pressure and volume, must comply with PED regulations. Equipment such as fire extinguishers, pressure gauges, valves, safety valves, air tanks, tower tanks, pipes, fittings, steam equipment, etc. for loading or conveying fluids must comply with PED regulations.Pressure equipment and assemblies with a maximum pressure above 0.5 bar."Pressure equipment" means vessels, pipes, safety parts and pressure parts.PED is applicable to European Economic Area EEA countries, namely EU 15 countries (Austria, Belgium, Denmark, Germany, Greece, Spain, France, Ireland, Italy, Luxembourg, Netherlands, Portugal, Finland, Sweden, UK), Plus the members of the European Free Trade Agreement (Iceland, Liechtenstein, Norway).Pressure equipment and components above a specific pressure/volume threshold must:l With securityl Meets basic safety requirements for design, manufacture, and testingl Meet appropriate compliance assessment proceduresl Attach the CE mark and the mark of the relevant regulationsPressure equipment and components below a specific pressure/volume threshold must:l With securityl Design and manufacture according to sound engineering practicel Label with relevant regulations (CE mark may not be attached)All pressure equipment in the PED category must meet the basic safety requirements mandatory:(1) Design: All factors related to the intended use must be considered in the design of pressure equipment to ensure the safety of pressure equipment throughout its expected life. The corresponding safety factors must be incorporated in a comprehensive approach, and sufficient safety margins must be considered for all relevant failure modes.Requirements are provided for the design and calculation of sufficient strength, ensuring safe handling and operation, inspection methods, discharge and venting methods, corrosion and other chemical erosion, wear, charging and discharging, protection in case of exceedance of permissible limits, safety accessories and external fire.(2) Permanent connection (welding) : must be done by qualified personnel according to appropriate process procedures. For Class II, III and IV pressure equipment, procedures and personnel must be approved by the authorizing authority or a third party authorized by the Member State under Chapter 13.(3) Non-destructive testing: Non-destructive testing of permanent connections (welds) of pressure equipment must be performed by qualified personnel. For CLASS III and IV pressure equipment, the NDT personnel must be approved BY a third party accredited by the Member State under Chapter 13.(4) Final assessment; Pressure equipment must pass visual assessment and final inspection of relevant documentation. The final assessment must include a pressure test, which must meet the specified values.(5) Material: The material used to manufacture pressure equipment must be adequate for its expected life. The manufacturer must, in its technical document, state the main points of material specification in one of the following forms: 1) the use of materials in conformity with harmonised European standards; 2) Adopt pressure equipment materials approved by Europe according to Chapter 11; 3) Use specially assessed materials; For Class III and IV pressure bearing equipment, the specific assessment of materials must be carried out by an authorized authority.(6) quantitative requirements: 1) allowable stress: such as including normalizing (normalizing rolling) steel including ferritic steel (excluding fine grain steel and special heat treatment steel), shall not exceed the yield limit at 2/3 calculated temperature and the strength limit at 20℃ of 5/12; 2) Joint coefficient: 1 when all joints are confirmed to have no obvious defects by destructive test and nondestructive test of equipment; The random nondestructive test of the equipment was 0.85; 0.7 for external inspection of equipment without nondestructive testing; 3) Pressure limiting device: instantaneous pressure movement must be kept within 10% of the maximum allowable pressure; 4) Hydrostatic test pressure: shall not be less than the maximum load that may be subjected to in the bearing equipment service, considering the maximum allowable pressure and maximum allowable temperature multiplied by the corresponding coefficient 1.25 or the maximum allowable pressure multiplied by the coefficient 1.43, the maximum value of the two shall be taken; 5) Material properties: tensile test at not more than 20℃ and not more than the lowest predetermined operating temperature, the elongation after fracture is not less than 14%, and the impact failure energy of the ISO Charpy V-shaped sample is not less than 27J.Main work editor broadcast(1) Design approval; Provide the list of standard specifications used in design and manufacturing, internal standards of the enterprise, product drawings, calculations, material lists, comparative analysis of PED "basic safety requirements" compliance, hazard analysis, operation instructions, product conformance statement, etc.(2) Material approval. Provide material warranty, additional tests if necessary, supplier review of outsourced materials;(3) Welding process and welder evaluation: make evaluation plan, compile welding process specification (WPS), prepare welding test plate and welding material, and conduct process evaluation and welder evaluation test;(4) Accreditation of non-destructive testing personnel;(5) Quality system approval: provide quality manual, two annual audit reports, inconsistency items and correction records, supplementary procedure documents meeting PED requirements, etc.Selection of product classification and conformity evaluation modeManufacturers MUST ANALYZE AND categorIZE THEIR PRODUCTS TO MEET THE PED REQUIREMENTS FOR DIFFERENT PRESSURE DEVICES. Products CAN BE CLASSIFIED INTO FIVE CATEGORIES: PED CLAUSE 3.3(DESIGNED AND MANUFACTURED IN ACCORDANCE WITH THE SOUND ENGINEERING PRACTICES OF MEMBER STATES), AND FIVE CATEGORIES I TO IV. The higher the risk, the higher the classification and the stricter the rules.PED compliance assessmentThe conformity assessment procedure applies to equipment in categories I to IV.The combination of vendor choices is as followsClass I, Class II, Class III, Class IVA A1 B1+D B+DD1 B1+F B+FE1 B+E GB+C1 H1HFor products that only apply the lower requirement mode, the manufacturer may choose to apply the higher requirement mode.The modes are described as follows:A Internal production controlA1 Internal manufacturing inspection plus final review supervisionB EC type inspectionB1 EC Design checkC1 conforming typeD Production quality Assurance (ISO 9002)D1 Production Quality Assurance (ISO 9002)(Mode separate application)E Product quality Assurance (ISO 9003) final inspection and testingE1 product quality Assurance (ISO 9003)(Mode separate application)F Product InspectionG EC Individual checkH Total Quality Assurance (ISO 9001)H1 Total Quality Assurance (ISO 9001) plus special monitoring for design inspection and final assessmentMode A does not have to be verified by the notified body, whereas each other must be verified by a notified body recognized by the Member States of the European Union.Quality assurance regulations and technical regulationsPED includes provisions on quality assurance and technology. Both of them are mandatory for the manufacturer and the product. Only when both of them meet the requirements, the pressure equipment products produced can be affixed with the CE mark. In China, a number of foreign institutions can provide factory commodity insurance and technical verification services.

-

-

-

-

Abide by contracts and keep promises/quality service integrity enterprise

Issuing authority : Zhenghe Dingxin International Credit Rating Co., L

Valid period : 2022/3/5 - 2025/3/4

It is a kind of credit certification. Enterprises that declare to honor contracts and keep credit shall meet the following basic conditions:(1) It has obtained various pre-approvals as required by laws and regulations (referring to various statutory pre-approval procedures or permits), and has obtained relevant certificates and licenses according to law;(2) having a business site consistent with the scale of its operations;(3) The company has been in business for more than two fiscal years with no operating loss and good economic benefits;(4) having a credit management organization, personnel and credit management system conforming to the characteristics of the enterprise;2. An enterprise that applies for honoring contracts and keeping good faith shall submit the following materials to the administrative department for industry and commerce where the enterprise is domicile:(1) an application;(2) a copy of the valid enterprise business license and copies of various types of administrative licenses;(3) a power of attorney signed by the legal representative (responsible person) of the enterprise to the filing agent;(4) Registration form of enterprises honoring contracts and keeping promises;(5) Copies of the enterprise credit (contract) management system, institutions and relevant documents of full-time (part-time) professional credit (contract) management personnel;(6) enterprise credit information evaluation form;(7) The Balance Sheet, Income Statement and Cash Flow statement audited by the accounting firm of the enterprise in the last two years;(8) In the case of applying for a contract-honoring and trust-keeping enterprise at a higher level, a copy of the certificate of the enterprise that has been recognized as a contract-honoring and trust-keeping enterprise shall be submitted;(9) other relevant materials required to be submitted by the accrediting authorities.

-

-

-

-

Enterprise Credit Rating Certificate/Enterprise Credit Rating Certificate

Issuing authority : Zhenghe Dingxin International Credit Rating Co., L

Valid period : 2022/3/5 - 2025/3/4

Enterprise credit rating certificate is the credit certificate of the enterprise in the operation period, and the evaluation certificate of the third party credit evaluation agency on the comprehensive quality of the enterprise. It directly reflects the overall integrity image of an enterprise, and is also a qualification to guarantee the credibility and influence of the enterprise.Enterprise credit rating reflects the level of enterprise credit. The higher the credit rating, the better the enterprise's operation status, contract performance and credit record. At present, the credit rating certificate can be divided into the following categories: AAA: the highest level of the certificate, the integrity management demonstration unit. The comprehensive quality of the enterprise is excellent, and its operation, solvency and credit status are relatively excellent. AA: The company has a strong repayment ability and basically has no risk. A: The enterprise has a strong ability to pay interest, but it is easily affected by external uncertainties, but the risk is relatively low. BBB: The enterprise has a certain ability to pay and control risks, and can protect the interests of customers. BB: The credit of the enterprise is not good, and it belongs to speculative grade enterprise. Most of the qualities are normal, with great uncertainty and high risk of default. B: The credit of the enterprise is poor, and the ability of the enterprise to control risks cannot be proved, and the solvency is weak. CCC: The credit of the enterprise is very poor, and it has almost no solvency. CC: Enterprise credit is very bad. Enterprises with grade C and grade D basically have no credit to speak of. Among them, enterprises with grade C are on the verge of default and have very weak ability to repay capital and interest. Enterprises with grade D are in default. In general, there are many benefits of enterprise credit rating, which is not only widely used in the field of bidding, but also in enterprise publicity, foreign contract signing, government procurement plan and so on. Good credit status will give enterprises appropriate bonus points. Therefore, more and more enterprises are dealing with enterprise credit rating certificate, at present, the country is more encouraged and recognized, are the credit report issued by the third party credit service agencies.

-

-

-

-

Integrity Management Teacher Unit Certificate / Integrity Supplier Certificate

Issuing authority : Zhenghe Dingxin International Credit Rating Co., L

Valid period : 2022/3/5 - 2025/3/4

China Honest supplier certification is a process of verifying and verifying the credit information of the entity enterprise and publishing it on China Business Credit Platform. It is a powerful proof of authenticity and legitimacy given to the enterprise by the third party, which is conducive to improving the market competitiveness and brand reputation of the enterprise. Business information includes registration information, quality certification information, qualification information, contact information and so on. The validity period is one year, starting from the date the enterprise passes the certification.The product features1. National enterprise credit certificate, nationally accepted and internationally recognized;2. The third-party enterprise credit assessment shall be open, fair and just;3. High-end authoritative release channels to quickly establish an image of corporate integrity;4. Quickly query enterprise credit information through mobile Internet.For supplier selection, through the qualified supplier credit rating certification can be regarded as one of the conditions of excellent supplier qualification, many suppliers to participate in the bidding project need this certification qualification certificate, the certificate is valid for 3 years, but the premise is that the enterprise must accept the supervision and audit of the certification body, that is, the annual audit; The frequency of supervision and audit is generally once every 12 months, that is, once a year, so it is also called annual audit; Some enterprises may be more special, the institution will require 6 months or 10 months to review once a year; If the certificate is not approved or replaced after the deadline, the certificate will be expired or invalid and cannot be used normally.

-