A valve to block the backflow of medium

sourcebaidu

publisherAlex

time2022/07/11

- A valve to block the backflow of medium

Check valve

A valve to block the backflow of medium

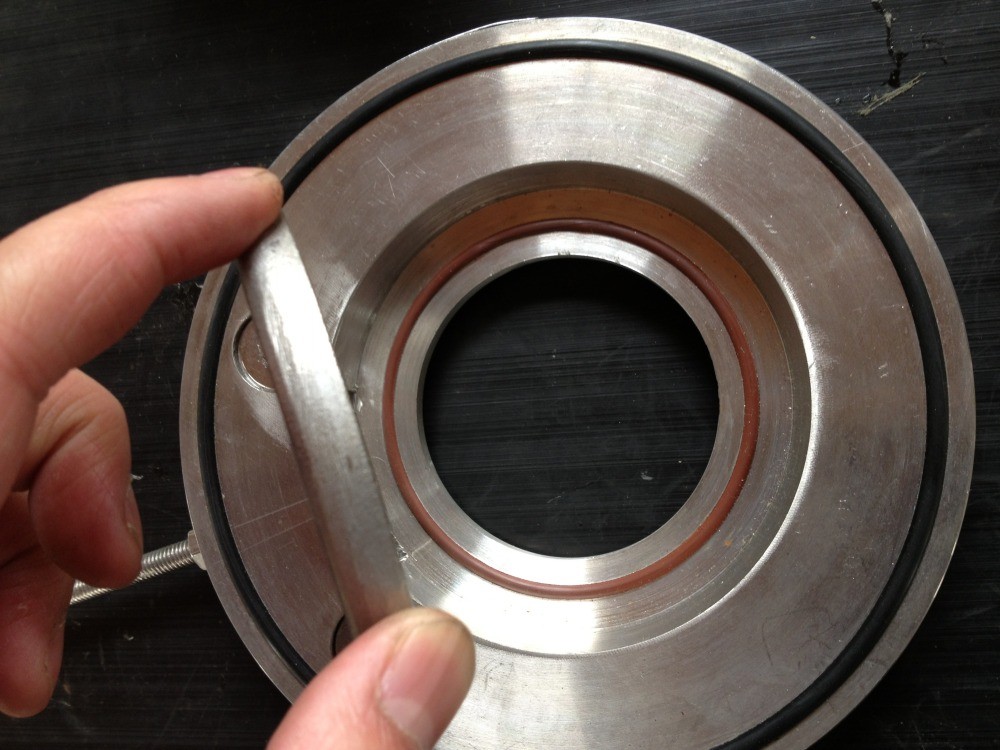

Check valve refers to a valve with a circular valve disc as its opening and closing part and acting by its own weight and medium pressure to block the backflow of medium. It is an automatic valve, also known as check valve, one-way valve, return valve or isolation valve. The movement mode of valve disc is divided into lifting type and swing type. The structure of lift check valve is similar to that of stop valve, only lacking the stem to drive the valve disc. The medium flows in from the inlet end (lower side) and out from the outlet end (upper side). When the inlet pressure is greater than the sum of the disc weight and its flow resistance, the valve is opened. On the contrary, the valve is closed when the medium flows back. Swing check valve has an inclined disc that can rotate around the shaft, and its working principle is similar to that of lift check valve. Check valve is often used as the bottom valve of pumping device, which can prevent the backflow of water. The combination of check valve and stop valve can play the role of safety isolation. The disadvantage is high resistance and poor sealing when closing.

working principle

The check valve can also be used to supply the auxiliary system whose pressure may rise above the system pressure. Check valves are mainly divided into swing check valves (rotating according to the center of gravity) and lift check valves (moving along the axis).

The function of this type of valve is to allow the medium to flow in one direction only, and to prevent the flow in the opposite direction. Usually, this valve works automatically. Under the pressure of fluid flowing in one direction, the valve disc opens; When the fluid flows in the opposite direction, the fluid pressure and the self weight of the valve disc act on the valve seat to cut off the flow.

The check valve belongs to this type of valve, which includes swing check valve and lift check valve. Swing check valve has a hinge mechanism, and a valve disc like a door freely rests on the inclined valve seat surface. In order to ensure that the valve clack can reach the appropriate position of the valve seat surface every time, the valve clack is designed in the hinge mechanism, so that the valve clack has enough swing space and makes the valve clack truly and comprehensively contact the valve seat. The valve disc can be made of metal, or inlaid with leather, rubber or synthetic coverage, depending on the requirements of service performance. When the swing check valve is fully opened, the fluid pressure is almost unimpeded, so the pressure drop through the valve is relatively small. The disc of the lift check valve is located on the sealing surface of the valve seat on the valve body. Except that the valve disc can rise and fall freely, the rest of the valve is like a stop valve. The fluid pressure lifts the valve disc from the sealing surface of the valve seat, and the medium backflow causes the valve disc to fall back to the valve seat and cut off the flow. According to the service conditions, the valve disc can be of all metal structure, or it can be in the form of inlaying rubber pads or rubber rings on the valve disc frame. Like the stop valve, the passage of fluid through the lift check valve is also narrow, so the pressure drop through the lift check valve is larger than that of the swing check valve, and the flow of the swing check valve is rarely limited.